When Starting a Centrifugal Pump, Must the Outlet Valve Be Closed?

Apr. 08, 2024

When starting a centrifugal pump, you need to pay attention to many things, but do you need to close the outlet valve when starting a centrifugal pump? Let’s find out together:

Why should the outlet valve be closed when a centrifugal pump is started?

When the centrifugal water pump starts, there is no water in the outlet pipeline of the pump, so there is no pipeline resistance and lifting height resistance. After the centrifugal pump starts, the centrifugal pump head is very low and the flow is very large. At this time, the pump motor (shaft Power) output is very large (according to the pump performance curve), and it is easy to be overloaded, which will damage the pump motor and circuit. Therefore, the outlet valve must be closed when starting to allow the pump to operate normally.

If you use an axial flow water pump, the situation is the opposite. It must be started by opening the valve. At this time, the power of the motor is at its minimum and there is no resistance in a short period of time, so it will run at a high flow rate. Pump vibration, noise, and even motor overload operation often occur. Burn the motor. Closing the outlet valve is equivalent to artificially setting the pipe resistance pressure. After the pump operates normally, slowly start the valve to allow the pump to gradually work normally along its performance curve.

Two points must be ensured before starting the centrifugal pump:

1. Fill the pump housing with water in order to create a vacuum;

2. The gate valve on the water outlet pipe must be closed so that the water pump does not form a flow, which can reduce the starting current of the motor and facilitate the smooth start of the water pump. As the water pump starts smoothly, the gate valve should be opened slowly in time.

The centrifugal pump relies on the centrifugal force of the impeller to create a vacuum suction to lift the water. Therefore, when the centrifugal pump is started, the outlet valve must be closed first and water is filled. The centrifugal pump can only be started when the water level exceeds the impeller part and the air in the centrifugal pump is discharged. After starting, a vacuum is formed around the impeller, sucking the water upward, and it can automatically open and lift the water. Therefore, the outlet valve must be closed first.

About centrifugal pumps

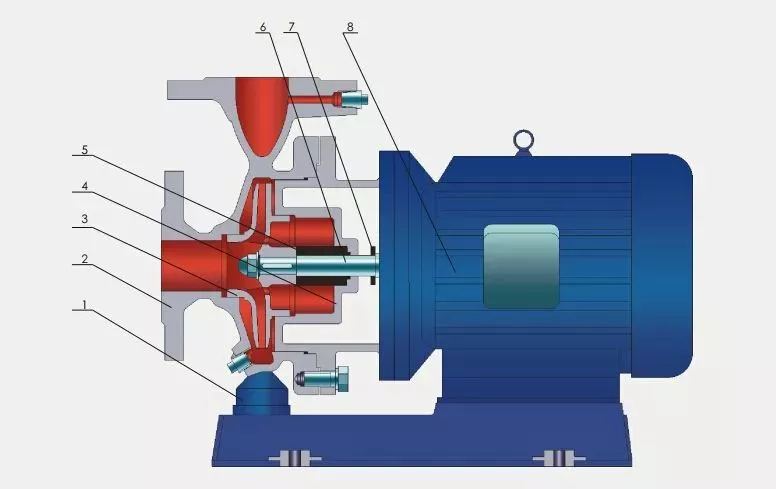

The centrifugal pump is a vane pump that relies on the rotating impeller to transfer mechanical energy to the liquid due to the interaction between the blades and the liquid during the rotation process, so that the pressure of the liquid can be increased to achieve the purpose of transporting the liquid. The centrifugal pump has the following characteristics:

①The lift generated by the centrifugal pump at a certain speed has a limited value. The operating point flow rate and shaft power depend on the conditions of the device system connected to the pump (position difference, pressure difference and pipeline loss). The head changes with the flow rate.

② Stable operation, continuous transportation, and no pulsation in flow and pressure.

③ Generally, there is no self-priming ability. The pump needs to be filled with liquid or the pipeline must be evacuated before it can start working.

④ The centrifugal pump is started with the discharge pipe valve closed, and the vortex pump and axial flow pump are started with the valve fully open to reduce starting power.

Before the pump starts, the pump casing is filled with the liquid to be transported; after it starts, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate with it. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and gains energy, leaving the outer edge of the impeller at high speed and entering the volute pump casing.

In the volute, the liquid slows down due to the gradual expansion of the flow channel, and converts part of the kinetic energy into static pressure energy. Finally, it flows into the discharge pipe at a higher pressure and is sent to the required location. When the liquid flows from the center of the impeller to the outer edge, a certain vacuum is formed in the center of the impeller. Since the pressure above the liquid level in the storage tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller. It can be seen that as long as the impeller continues to rotate, liquid will continue to be sucked in and discharged.

Starting of other centrifugal pumps

The above mentioned are all centrifugal pumps. For other types of pumps, the situation is as follows:

1. Large flow starting characteristics of axial flow pump - fully open valve starting

The shaft power of the axial flow pump is maximum at zero flow condition, which is 140%~200% of the rated shaft power. The power is minimum at maximum flow. Therefore, in order to minimize the starting current, the starting characteristic of the shaft power should be large flow start (i.e. fully open). valve starts).

2. Starting characteristics of mixed flow pump - fully open valve starting

When the mixed flow pump operates at zero flow, the shaft power is between the above two pumps, which is 100% to 130% of the rated power. Therefore, the starting characteristics of the mixed flow pump should also be between the above two pumps, and it is best to fully open the valve. start up.

3. Starting characteristics of vortex pump - fully open valve start

The shaft power of the vortex pump is maximum under zero flow condition, which is 130% to 190% of the rated shaft power. Therefore, similar to the axial flow pump, the starting characteristic of the vortex pump should be large flow start (that is, fully open valve start).

254

0

0

Comments

All Comments (0)