The Positive and Negative Effects of the Regulating Valve and Air Opening and Air Closing, Flow Opening and Flow Closing

Apr. 08, 2024

The air opening-air closing of the regulating valve is relative to the entire regulating valve. As the gas pressure in the diaphragm head increases, the valve gradually opens to a gas-open valve. As the gas pressure in the diaphragm head increases, the valve gradually closes to a gas-closed valve. When there is no signal, the air-opening valve is in a closed state and the air-closing valve is in a fully open state.

The direct action-reaction of the control valve is relative to the actuator of the pneumatic diaphragm control valve. The upper part of the diaphragm head takes in air and the push rod moves downward, which is called the forward action. The lower part takes in air and the push rod moves upward called reaction.

Flow open-flow closed is for the medium. When the flow direction of the orifice medium flows toward the opening direction of the valve, it is called an open flow type. On the contrary, when the flow direction of the medium flows toward the closing direction of the valve, it is a closed flow type.

1. Functional form of pneumatic actuator

(1) Positive and negative effects of pneumatic actuators. When the input air pressure of the pneumatic actuator increases, the push rod moves downward, which is called positive action; on the contrary, when the input air pressure increases, the push rod moves upward, which is called reaction action.

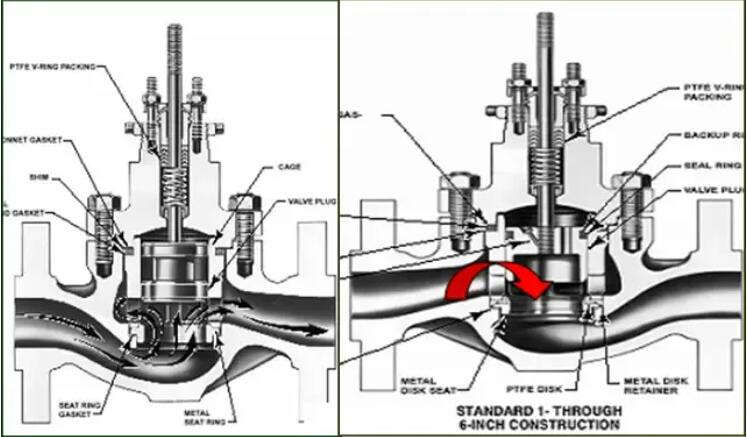

(2) Formal and reverse installation of the adjustment mechanism. The valve core has two forms: formal installation and reverse installation. When the valve core moves downward, the flow cross-sectional area between the valve core and the valve seat decreases, which is called a positive valve. On the contrary, when the valve core moves downward, the flow cross-sectional area increases, which is called a reverse valve. For double-guided front-mounted valves, as long as the valve stem is connected to the lower end of the valve core, it is a reverse-mounted valve. Valves with nominal diameter Dg<25mm are generally single-guided, so only formal valves are available.

(3) Functional form of pneumatic actuator. Pneumatic actuators come in two forms: air-opening type and air-closing type. When the signal pressure increases, the valve opens, which is called the air-opening type; conversely, when the signal pressure increases, the valve closes, which is called the air-closing type. Since the actuator has positive and negative effects, the regulating valve (with a double guide spool) also has positive and negative effects, so the air opening or air closing of the pneumatic actuator is composed of this combination.

For small-diameter control valves, the positive and negative effects of the actuator are usually changed to achieve air opening or air closing; for large-diameter control valves, the positive and negative effects of the control valve are usually changed to achieve air opening or air closing.

2. Locator

The positioner is used with a pneumatic diaphragm actuator.

1) The positive effect of the valve positioner: when the input signal increases, the air pressure output to the membrane head increases;

2) The reaction of the valve positioner: when the input signal increases, the air pressure output to the membrane head decreases;

The positive-acting actuator cooperates with the positive-acting positioner to realize the function of the positive-acting actuator;

The direct-acting actuator and the reaction positioner cooperate to realize the function of the reaction actuator;

The reaction actuator cooperates with the positive positioner to realize the function of the reaction actuator;

The reaction actuator cooperates with the reaction positioner to realize the function of the direct acting actuator;

3. FC (gas open or fault closed) or FO (gas closed or fault open) of the regulating valve

The choice of gas opening and gas closing is based on the safety perspective of process production.

When the air source is cut off, is the valve in the closed position or the open position safe? For example, in the combustion control of a heating furnace, the regulating valve is installed on the fuel gas pipeline to control the supply of fuel according to the temperature of the furnace or the temperature of the heated material at the outlet of the heating furnace. At this time, it is safer to use air-open valve.

The air-opening regulating valve means that the valve is fully closed when the air is cut off, and will only open when there is air. The valve is closed when there is no signal, and will open only when the signal is input. And the greater the signal, the greater the valve opening. The valve is fully open when the signal is maximum.

Air to Open type means that when the air pressure on the diaphragm head increases, the valve moves in the direction of increasing opening. When the upper limit of the input air pressure is reached, the valve is in a fully open state. Conversely, when the air pressure decreases, the valve moves in the closing direction. When there is no input air, the valve is fully closed. Therefore, sometimes air-to-open valves are also called fail-to-close (FC) valves.

The action direction of the air to close type is exactly opposite to that of the air to open type. When the air pressure increases, the valve moves in the closing direction; when the air pressure decreases or disappears, the valve moves in the opening direction or until it is fully open. Therefore, it is sometimes called Fail to Open (FO). Then during use, several fault locations that usually occur are (FO, FC, FL). The fault in the valve fault close/fault open refers to: the action of the valve when the air source fails.

For the fault location of pneumatic valves, there are mainly several situations:

1. When the pneumatic valve device interlocks, the valve position should have the following conditions:

FC-Air supply lost, valve in closed position

FO-air supply lost, valve in open position

FL-The air source is lost, the valve is in the instant position and remains

FLC-The air source is lost, the valve maintains its position but tends to close, and the valve is in the closed position (the gas in the cylinder is exhausted)

2. When the regulating valve or switch valve participates in the interlocking action of the device, the valve position should be as follows:

FC-The air source is lost or the solenoid valve loses power, and the valve is in the closed position;

FO-The air source is lost or the solenoid valve loses power, and the valve is in the open position;

AFL/EFC-

1) When the air source is lost, the solenoid valve does not lose power and the valve remains in position;

2) Regardless of whether the air source is lost or the solenoid valve loses power, the valve is in the closed position;

AFL/EFO-

1) When the air source is lost, the solenoid valve does not lose power and the valve remains in position;

2) Regardless of whether the air source is lost or the solenoid valve loses power, the valve is in the open position.

Pneumatic valves realize valve cutting, connecting, adjusting and other functions through output signals. Their opening and closing speed is relatively fast. They are often used for fast two-position cutting and can also be used to adjust flow. With different accessories, they can achieve various functions. to a variety of different control methods.

The flow area of the air-open control valve increases as the signal pressure increases; while the air-close type control valve, on the contrary, decreases as the signal pressure increases.

13

0

0

Comments

All Comments (0)